Leading the field of precision manufacturing

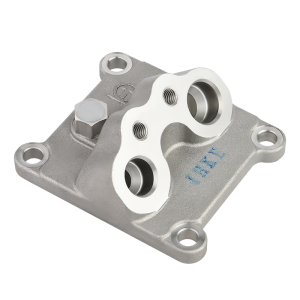

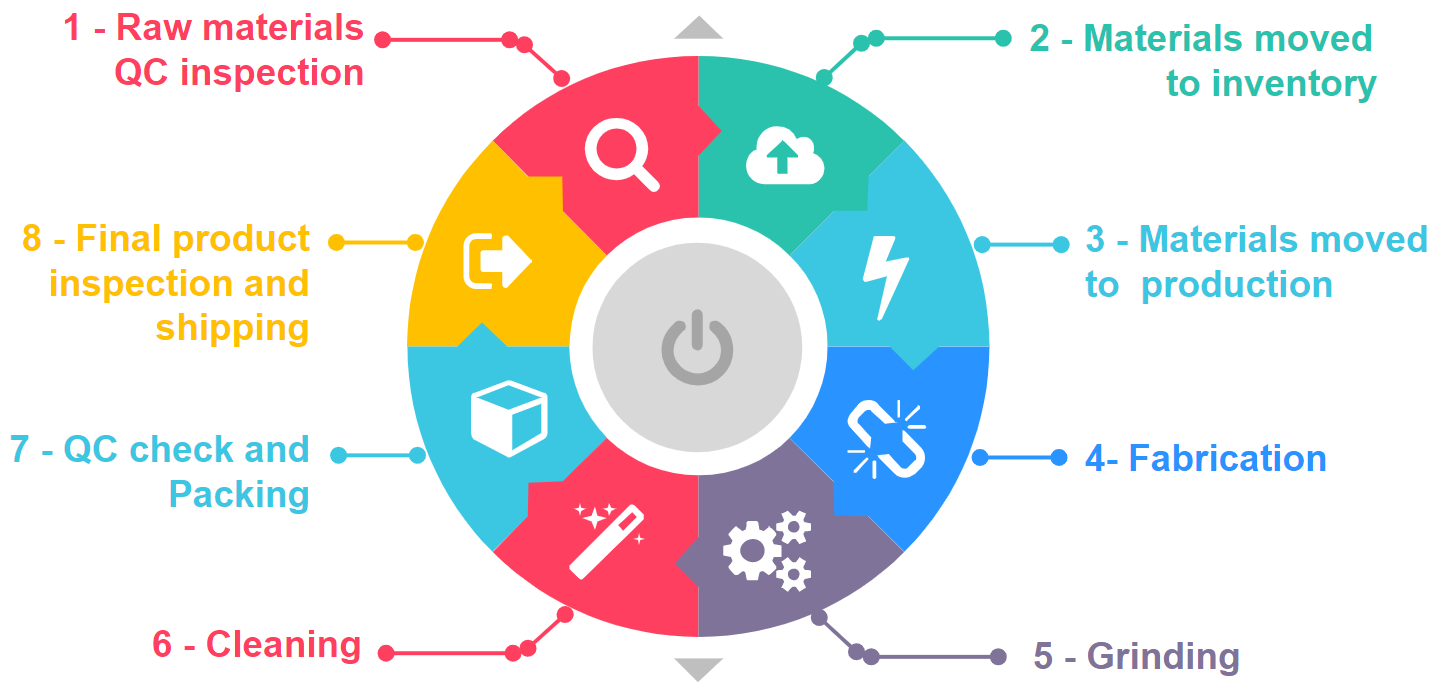

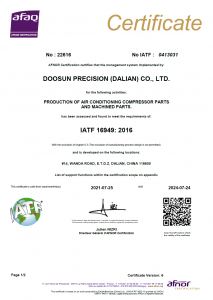

Established in 2005, after 20 years of sincere cooperation with Hyundai Motor Co., Doosun Precision Components has grown into a modern enterprise integrating precision process and manufacturing of automotive parts and new energy automotive parts. Mainly engaged in precision machining, manufacturing aluminum alloy and steel parts for automotive air-conditioning compressors, special high-strength fasteners, forged green parts, and automation development.

Our main customers are Hyundai Motor Company (South Korea), Changan Automobile (China), Great Wall Motor (China), Changan Ford (China), Fiat (Italy), Jaguar Land Rover (UK), Maxsun (South Korea), DaLian, and Takita